SOP: Standard Operating Procedure of Skewing / Twisting Test | Garments-Info

SOP – Skewing / Twisting Test

|

Standard Operating Procedure of Skewing / Twisting Test |

Objective

·

This

test aims to determine the yarn weaving distribution within the fabric cross

sectional area. Results will show the direction of fabric grain line.

·

To

identify probable Fitting and finishing defect caused by bowing fabric. This

type of defect not only affects the fitting of the garment (Twisting legs in

pants) but also affect the availability and/or presentation. It is less

noticeable in solid color but more critical on stripes or checks design.

·

To

be able to identify whether the fabric being inspected contains certain amount

of bowing or skews.

·

To

anticipate probable production difficulties and to prompt the factory in taking

immediate corrective steps in making markers and developing production

processes in order to ensure that garment shape shall not be distorted or

disfigured.

Scope

The procedure

covers one of the fabric inspection activities.

Authority

The procedure

is being controlled by the Head of Quality.

Responsibility

Execution and

proper maintenance of the procedure lies on the fabric inspector.

Procedure

·

The

fabric inspector shall identify the amount of skews and its location whether at

center or at sides.

·

The

fabric Inspector who needs to determine the amount of skews in the fabric shall

perform the following tasks.

·

Tear

8” from one end of the roll.

·

Align

the torn edge across a pre-drawn straight line on a table.

·

Check

for alignment and note down any distortion along the torn edge against the

pre-drawn line.

·

The

amount of skew can be measured by measuring the distance of skew from the

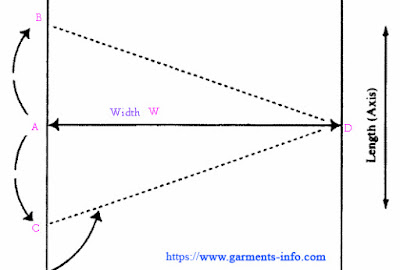

pre-drawn line. Refer to figure 1 below.

·

If

a torn edge is completely aligned with the pre-drawn line, fabric shows no

bowing problem.

·

Otherwise,

it indicates certain amount of skew or bowing on the fabric.

·

Formula

to determine the amount of skew (%) =

Distance of

skews (inches) AB or AC X 100

Fabric Width AD (Inches)

Tolerance

Customer/supplier

shall be immediately informed if the amount of skews exceeds 3% or as per buyer

standard.

Skewing/Twisting – If fabric fails for skewing/twisting.

·

Make

garment mock ups using normal/line marker and review the garments for twisting.

·

If

decision cannot be made, go for normal/Line markers to make actual garments.

Review these garments for twisting.

·

In

case of special marker required, need to get compensation from supplier.

Hope this article will help you to know about SOP of Skewing / Twisting Test.

Looking for a terminal crimping machine in your area ? Then we are the best for you, who suit your expectations. We have huge experience in this field. We are 100% dedicated to finding you a high quality terminal crimping machine.

ReplyDeleteIf you want to know more, Please check out Cheers Electronic Technical Co.LTD: https://www.terminal-crimping.com

This content is very useful for us, people can get important information from your article, and I can improve my skills. Many readers are satisfied with this content. I hope, people will also get benefits.

ReplyDeleteMaster Thesis Paper Help